Sunrise Corporate Park

Sunrise Corporate Park, Wagle Estate, Thane-Mumbai

Sunrise Corporate Park is an ongoing premium commercial development located in Wagle Estate, Thane–Mumbai, featuring approximately 1.6 million sq. ft. of built-up area (BUA).

The project comprises three G+17 storey commercial towers with multi-level parking and retail spaces at the lower levels. Designed with modern aesthetics and high-performance materials, the development integrates curved façade geometry at all corners, achieved through custom curved glazing systems.

The typical façade glazing uses Double Glazed Units (DGU) to enhance thermal performance, reduce solar heat gain, and improve energy efficiency, contributing to sustainable and comfortable office environments.

Key Technical Highlights & Challenges

- Complex Curved Geometry:The unique curved corners demanded precise engineering to resolve complex junctions and interface details, ensuring smooth visual continuity and flawless installation.

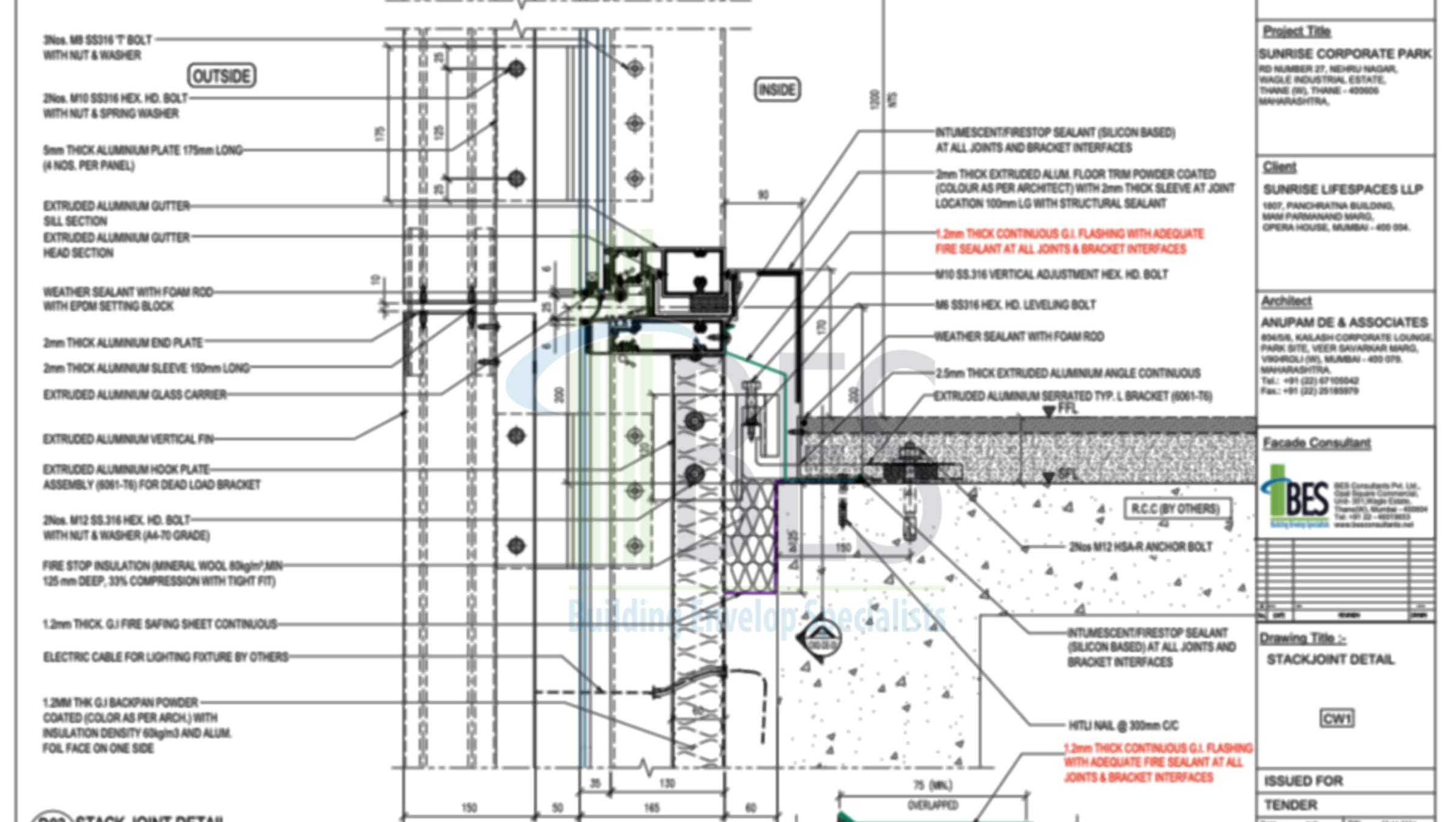

- Advanced Weatherproofing Solutions: Robust façade and louvre termination details were developed to achieve superior weather resistance and long-term durability in varying climatic conditions.

- Curved Roof Cladding Bands:The roof terraces feature curved metal cladding bands, seamlessly integrating architectural form and façade functionality.

- Adaptive Interior Interfaces:Façade systems and interface details were carefully designed to accommodate diverse office layouts, optimizing both aesthetics and performance.

Project Team

Client : Sunrise Group

Architect : Anupam De Associates

Project Status : Construction Stage

Scope :

- Typical Full scope covering Concept, DD, 3d Model, Tender Documentation and Construction stages

- Facade works Site Project Management - Full time site team deputation for Time and Quality management

BES Value Add:

BES implemented a bespoke façade system using advanced parametric 3D design tools, optimizing curved geometry and modular glass panels to balance aesthetics, cost efficiency, and constructability.

Our engineering solutions ensured:

- Simplified fabrication and site installation

- Enhanced energy efficiency through optimized DGU specification

- Improved quality control through pre-fabrication and mock-up validation

- Highly optimized Unitized Curtainwall system with reduced Aluminium weight/ Sqm. based on the wind loads and optimized for varying fin depths.

- Curved glazing usingUnitisedsystem featuring cladding bands curved in plan.

- Simplified interfaces with various office units and partition wall details and louvres for HVAC, detailed to achieve good weather proofing.

- Implmenting stringent QAQC system using BES inhouse developed digital quality management system.